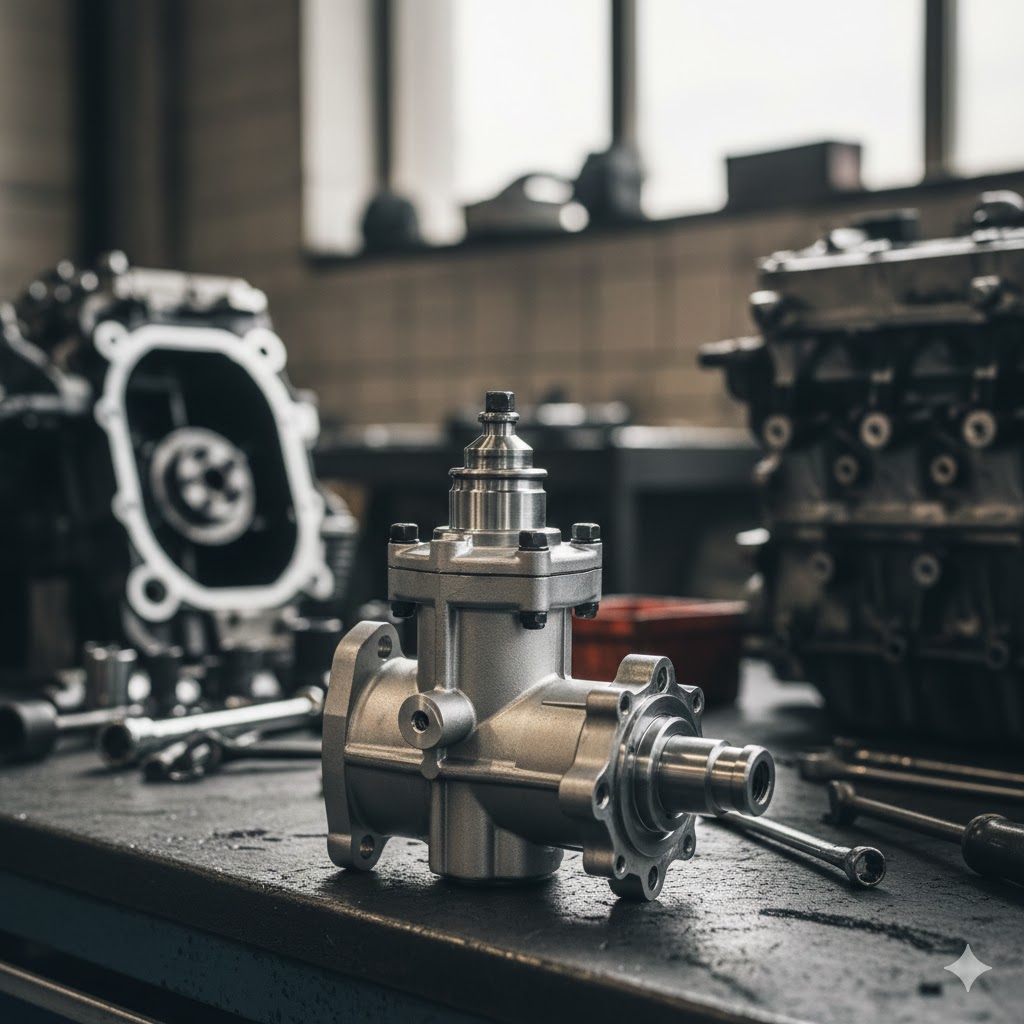

In the case of diesel engines, their performance and reliability are heavily dependent on a single component that is crucial which is the pump for injection. It is responsible to deliver fuel at the correct level, and at the correct time, and in just the proper quantity. If you’re operating a maintenance tractor, agricultural equipment or industrial machinery, picking the right pump is crucial to ensure smooth operation and longer engine life. There are a lot of Diesel injection pumps for sale on the market, knowing the best one will help you avoid costly errors.

Understanding the Role of a Diesel Injection Pump

The diesel injector is responsible for the flow of fuel between the tanks and the combustion chamber of the engine. As opposed to petrol engines depend on the delivery of high-pressure fuel to start properly. If your pump isn’t in good condition or is beginning to fail you might notice slow start, decreased efficiency of the fuel, rough idling or power loss. In the worst situations, an improper pump could cause an internal damage to your engine.

The reason for this is that choosing the correct injection pump isn’t only about the availability or cost. It’s about fitting the right pump for your engine’s needs.

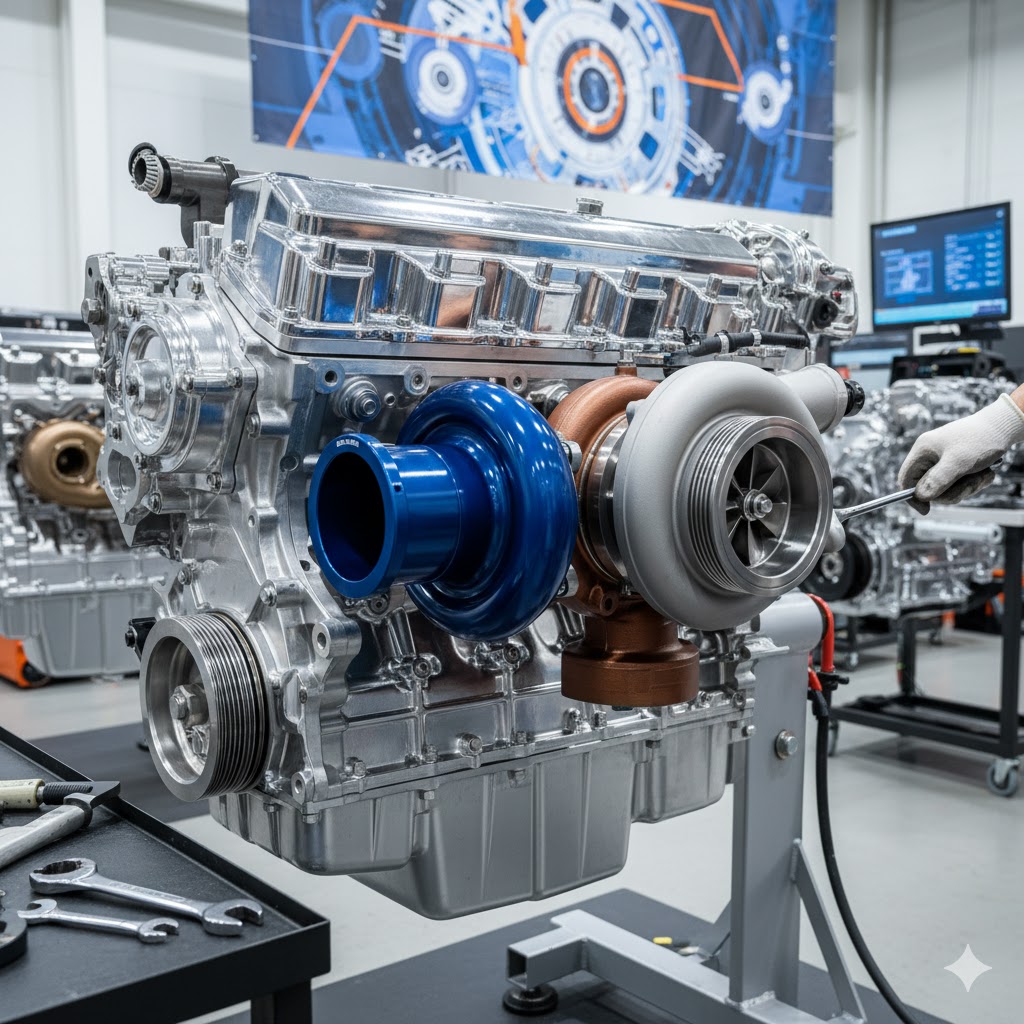

Know Your Engine Specifications

Before deciding on the right pump for your needs, it is essential to have to know the details of the engine. It is important to know the engine model number as well as the manufacturer, horsepower rating, and system type.

Knowing the type of engine your car requires can help narrow your choices and guarantees seamless integration.

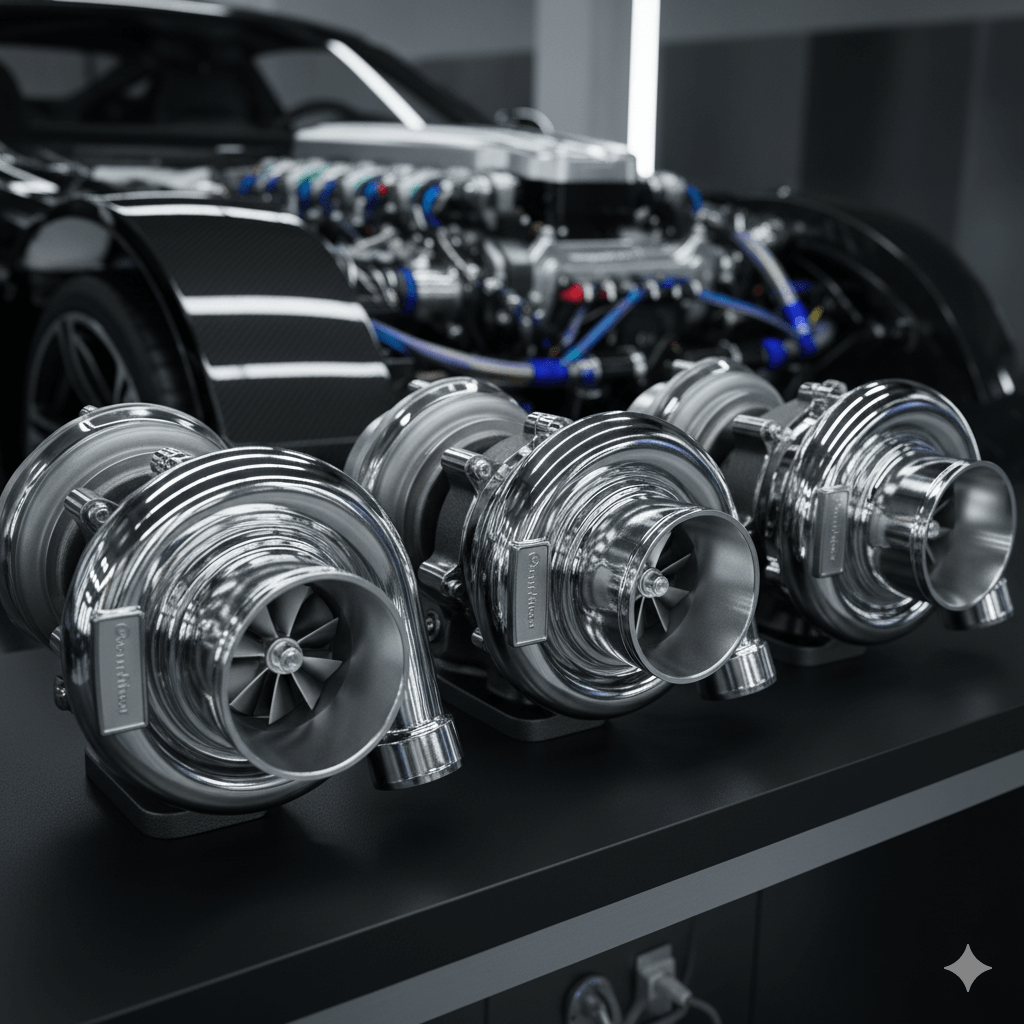

Remanufactured or recycled pumps tend to be cheaper and perform as well if repaired by a reputable supplier. They are tested, cleaned, and are fitted with new parts when they are required. For those who are budget conscious this could be an effective and reliable option.

Compatibility and Calibration Matter

Although a pump may fit physically, it should be properly calibrated for the engine you are using it on. The calibration ensures that the pump will deliver fuel at the precise pressure and time that your engine demands. An uncalibrated pump could result in an excessive amount of smoke or knocking sounds or an increase in fuel consumption.

Always ensure that the pump has been calibrated for the model of your vehicle or can be tuned professionally following the installation.

Choosing a Trusted Supplier

The reputation of the seller is as important just as that of the product itself. A reliable seller will offer precise information about the product as well as compatibility guidelines, testing certification, as well as customer service. They must also be clear about whether the pump was new or rebuilt. They should also be clear about whether the pump is used. Do not make a decision solely on the lowest cost.

Final Thoughts

Choosing the correct Diesel injection pump for your needs is a choice that has a direct impact on the efficiency of your engine, its capacity, and longevity. By understanding the requirements of your machine and choosing the right pump type, and copping from a dependable supplier, you can be assured of dependable performance, and lower mechanical problems latterly on. An appropriately-matched pump won’t only keep your engine running; it ensures that your work is uninterrupted without interruption.

Nozzle Masters specializes in repairing and rebuilding fuel injection systems made by reliable brands like Bosch, Stanadyne, Delphi, Denso, Zexel, Ambac and Yanmar. Their technicians work with up-to-date tools and manufacturer-approved data to ensure every injector meets original performance standards. Every rebuild goes beyond simple cleaning- nozzles are replaced and sealing surfaces are strictly finished as well as opening pressures acclimated to ensure dependable operation.